What is a slurry separator?

The principle of separating slurry is briefly explained: a slurry separator separates the solid and liquid substances from the medium to be separated. The result is separated slurry solids and thin slurry. Raw slurry usually has a dry matter content (DM content) of between 6 and 10%. Separation with a Paulmichl slurry separator can increase the DM content of the separated slurry solids to up to 32%. Our separators are also used in biogas plants to separate the solid and liquid components of the substrate.

Why separate slurry?

Separating slurry involves separating the slurry into liquid and solid substances, both of which can be utilised effectively on the farm:

The thin slurry that remains after separation is rich in fast-acting nitrogen. These nutrients are extremely valuable for fertilisation. By separating the slurry, the thin phase is absorbed more quickly into the soil and leaves less feed contamination on the field.

The solids that are separated during the separation process can either be finely spread on the field, delivered to biogas plants or used as bedding.

The versatile application possibilities of slurry separators bring many advantages to farmers, arable farmers and biogas plant operators.

- Improvement of the nutrient balance and more efficient fertilisation

- Slurry as a substitute for mineral fertiliser

- Less feed contamination and burns due to more free-flowing thin slurry

- Reduction in storage volume, application rates and transport costs

- Reduction in mixing costs

If you would like to know how you can optimise the benefits for your farm, please contact us and we will be happy to advise you.

Slurry separator in use -

Milchviehbetrieb Müller.

Curious about how our Paulmichl slurry separator is used on the farm? Mario Müller from the Müller dairy farm takes you to his farm and shows you how slurry separation works:

Finding the right separator when it comes to separating.

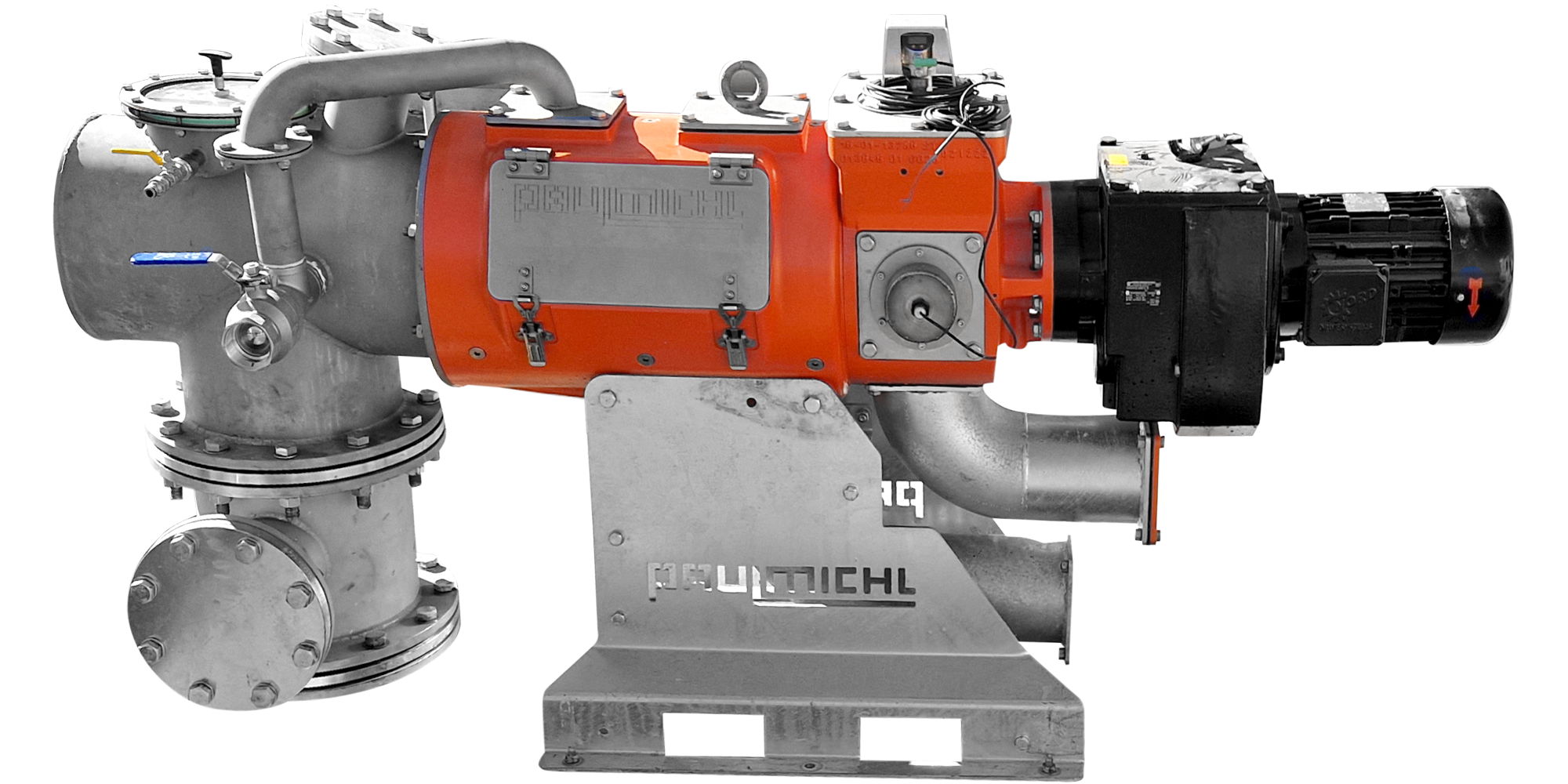

When selecting a slurry separator, there are various factors to consider to ensure that the slurry separator meets the requirements of your operation. We offer various slurry separators that can be customised depending on the location, dry matter content and required throughput capacity. Our separators are suitable for agricultural plants, contract operations, biogas plants, the food industry and waste recycling plants.

The throughput capacity of the slurry separator should be matched to the slurry requirements of your farm. Depending on the medium (pig slurry, cattle slurry, biogas substrate), we use different screen baskets to achieve the optimum dry substrate content. Depending on the operational conditions, your slurry separator can be installed on mobile and stationary structures. We offer mobile slurry separators with a high throughput capacity for contract farms and inter-company applications. Our service team is always available for maintenance or problems.

Get an overview of our separators for liquid manure and biogas here and let our experts advise you.

Advantages Advantages

Costs and subsidies

Slurry separators can be an investment, but the benefits mentioned above can pay for themselves in the long term. In some federal states, there are also subsidy programmes for the purchase of slurry separators or for biogas plants.

contact form

Write us a message.