From planning to commissioning

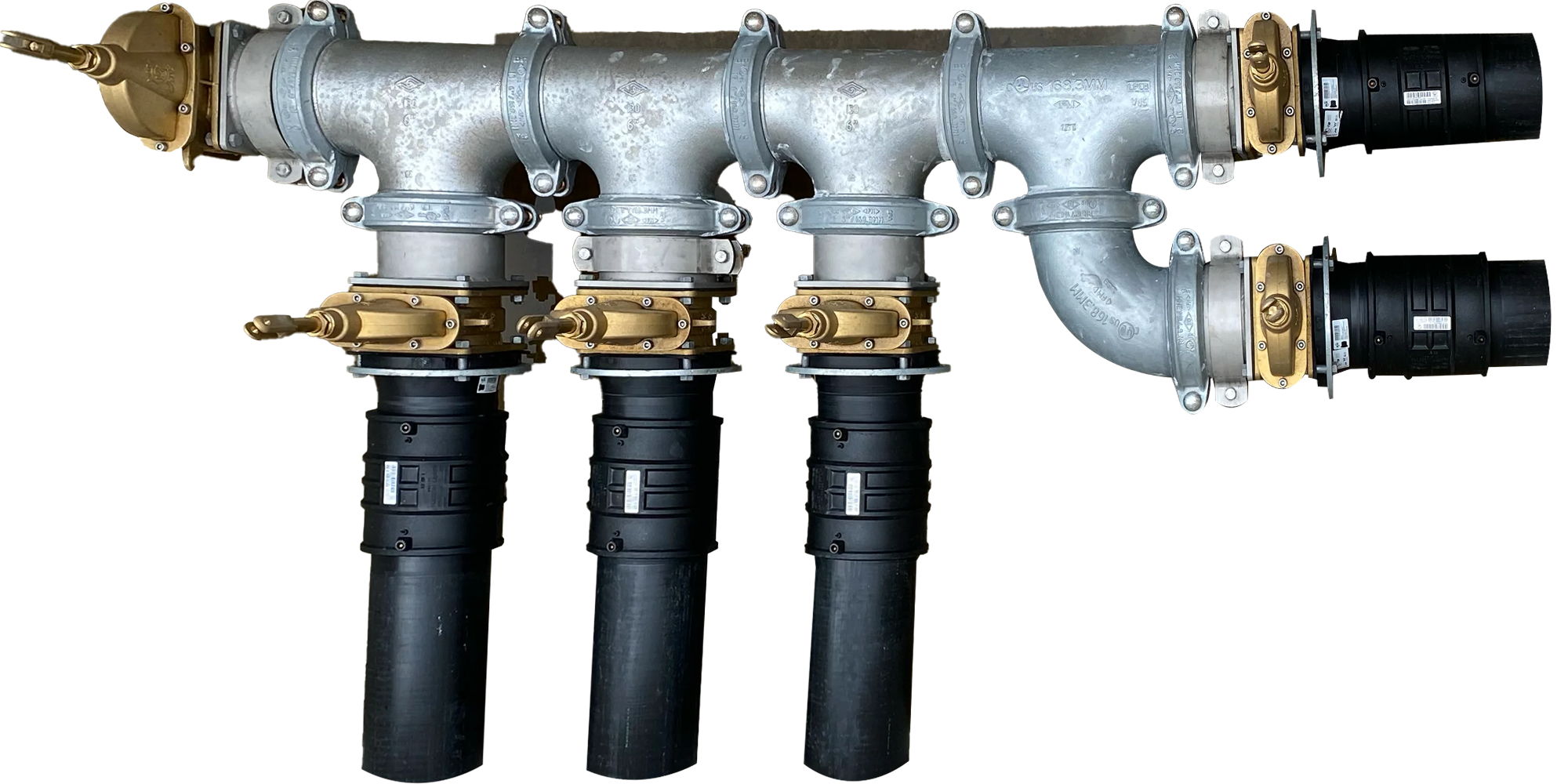

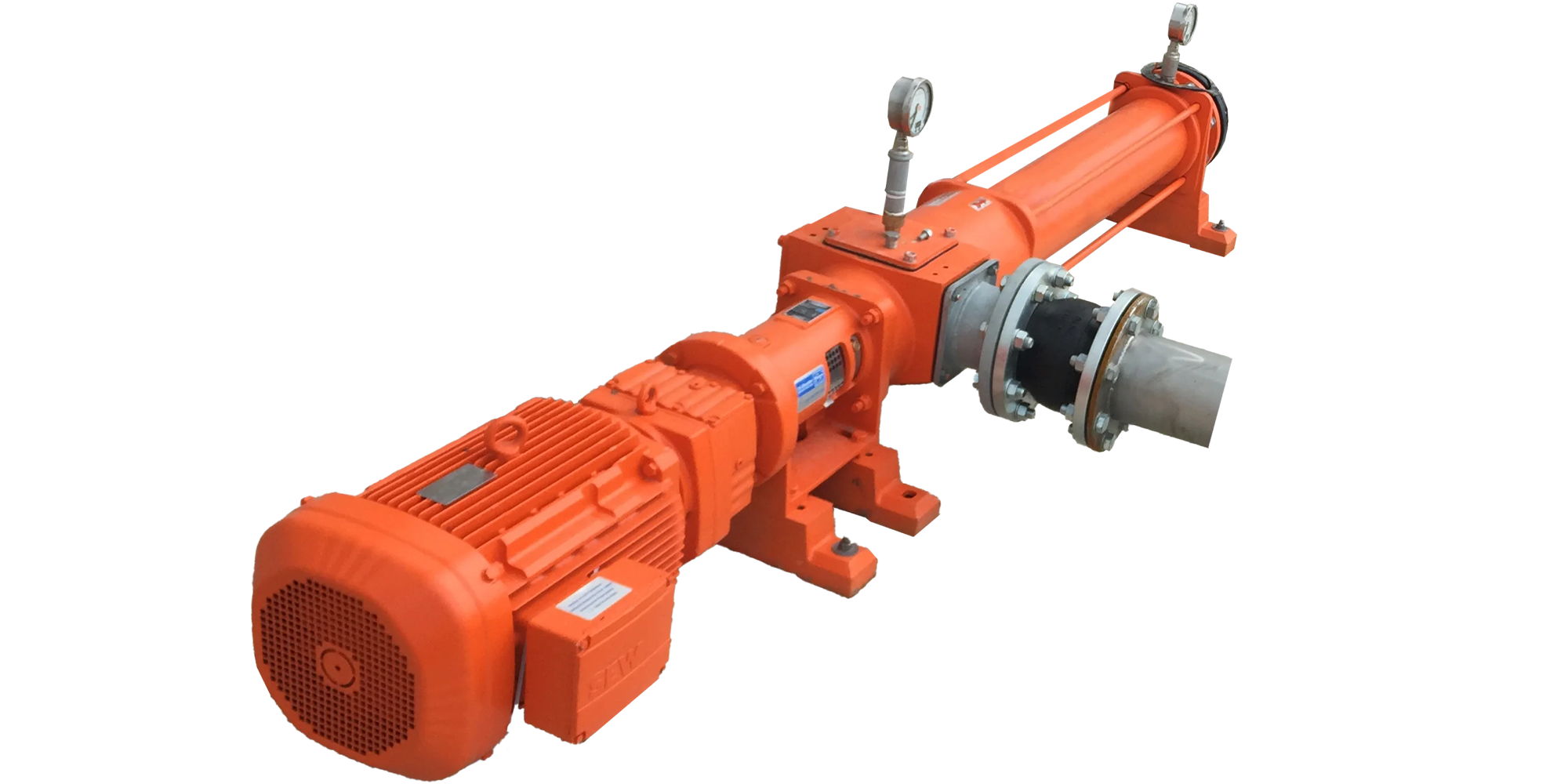

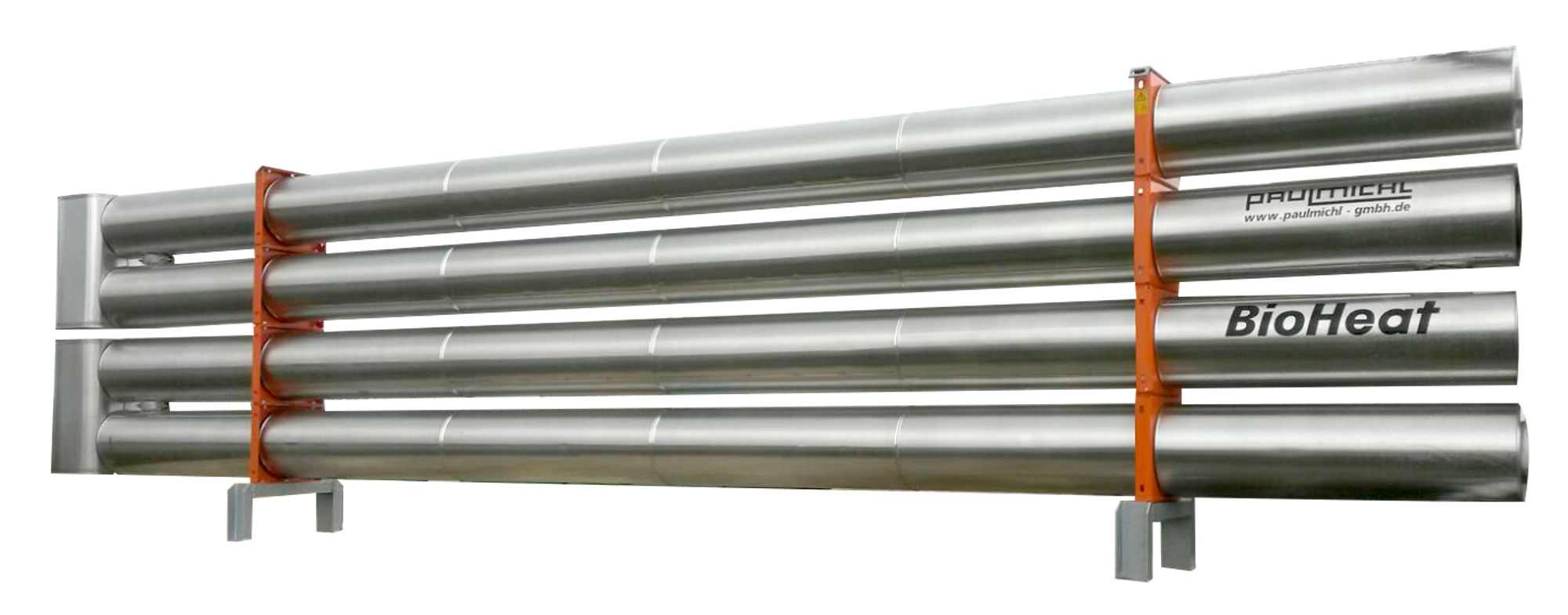

We offer the all-round carefree package for pipeline construction. Paulmichl is your expert when it comes to planning, laying and installing pipes. As a TÜV-certified specialist company in accordance with §19 WHG, Paulmichl pipeline construction is characterised by reliable and professional installation on site by our specially qualified specialists. Our services range from filling, extraction and gas lines to flushing and pumping lines. Customised special designs are also no problem.